Stable chemical performance: moisture-proof and damp-proof.

Stable physical performance: abrasion resistance and scratch resistance, hardness reaches 3H.

No VOC/HAP emissions, no odor

, No toxic, no heavy metal, no formaldehyde and no other toxic substances released.

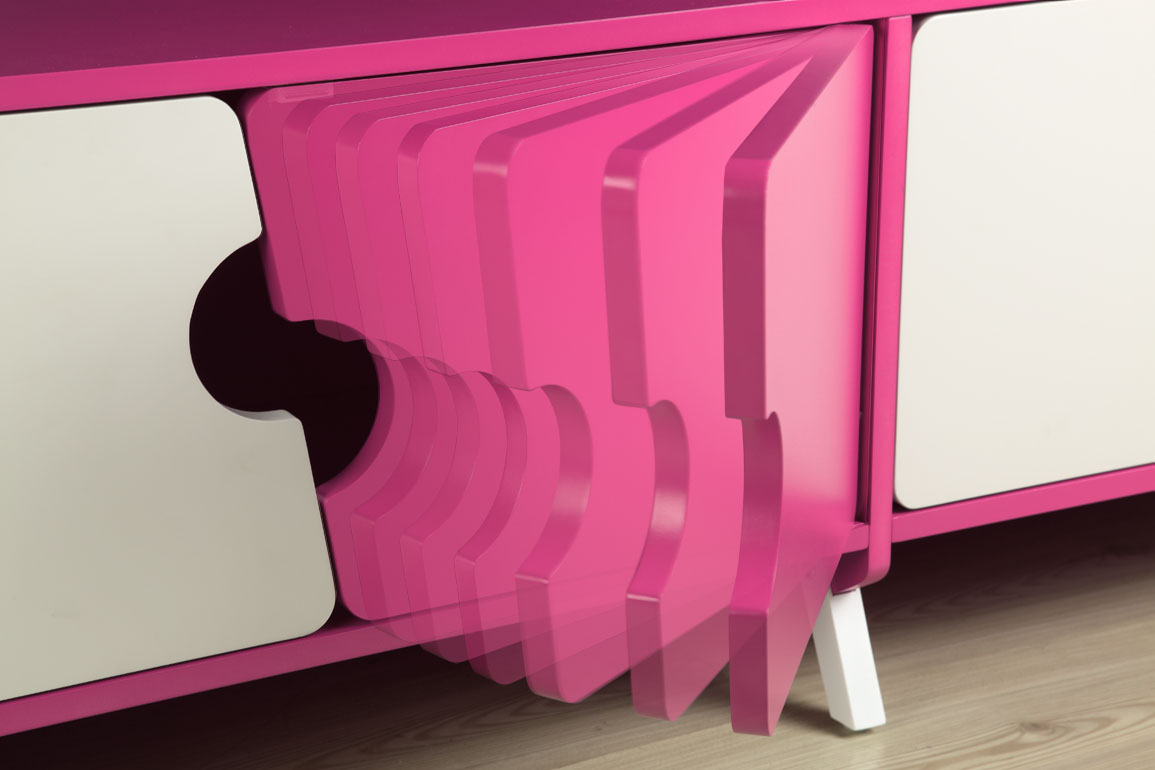

Seamless all around coating and no PVC banding.

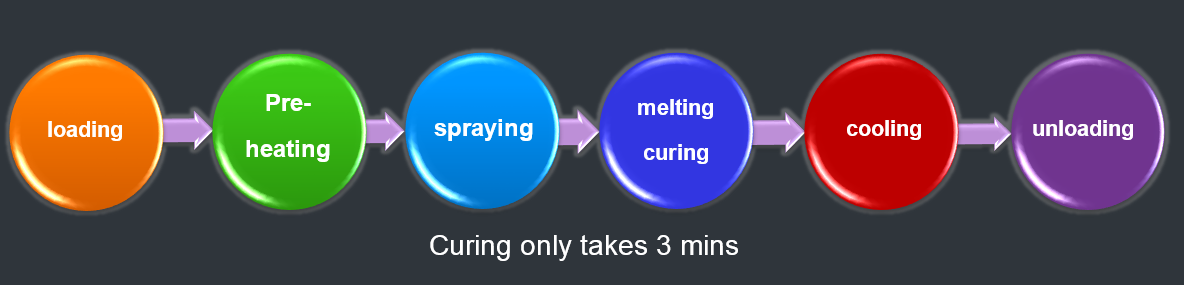

Powder coatings are solvent-free enamels. Through electrostatic spraying equipment, powder is applied to the wood substrate. In a subsequent curing process, the powder coating is melted and chemically cross-linked at substrate temperatures of 130-150 °C.

After powder coated, the surface of the product will form a seamless all around coating which make the product completely sealed for strong waterproof.

相比油漆和贴皮等表面处理方式,粉末涂料拥有最强的吸附力、牢固性以及最环保,粉末可使用率超过95%,且粉末本身无毒无味, 高效及环保.

Various colors could be selected from the PANTONE or other color swatches, and every batch of color maintains high consistency.

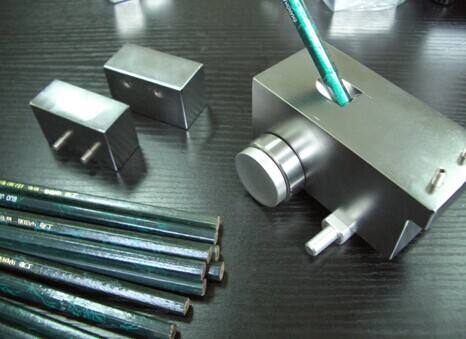

The workpiece enters the spray gun position through the conveying chain. The electrostatic generator releases high voltage electrostatic (negative) to the workpiece through the electrode pin of the spray gun muzzle, which makes the mixture of powder and compressed air carries negative charge. Thus forms an electric field between the spray gun and the workpiece and draw an uniform layer of coating on the workpiece. The whole process only takes 20 minutes.

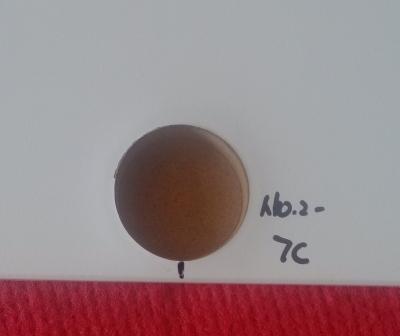

Drilling hole (hinge opening) next to an edge of the board, watering the hole, and put the board into the constant.

temperature humidity chamber: The edge of powder coated board remains uncracked for 48 hours.

If the hinge hole is treated with powder coating under the same test setup of 3 months, there are no cracks all sides.

Salmonella

Escherichia coli

Staphylococcus aureus

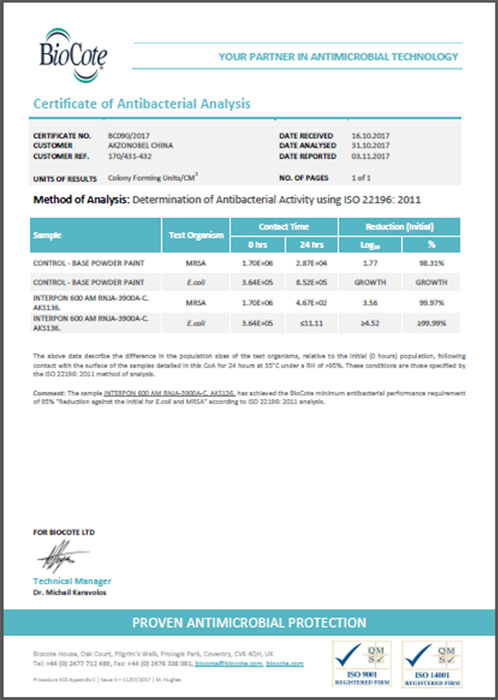

antibacterial test report

Bacteria: escherichia coli, staphylococcus aureus, salmonella

test method: ISO 22196:2011

Test result after 24 hours shows bacteria count reduced by over 99% on all types.

Antibacterial product create safer environment for home, medical treatment and education, let us safe in use, live at ease.